2 hours ago

What is a Chromebook? Top Pros and Cons

Chromebooks have emerged as standout devices with their unique approach to computing. Unlike traditional laptops, these devices combine simplicity, security,…

17 hours ago

Why More Businesses Are Automating Customer Interactions In 2025

A customer sends a message to a business at 2 a.m., expecting instant answers. While this sounds demanding, this is…

18 hours ago

How to Become an Amazon Affiliate in 2025

The world of eCommerce is expanding at a rapid pace and has become a lucrative option for individuals who are…

18 hours ago

Legit Ways of Making Money by Reviewing or Testing Products

Having the talent to articulate your opinion and experience with a product is an asset. Now, more and more people…

19 hours ago

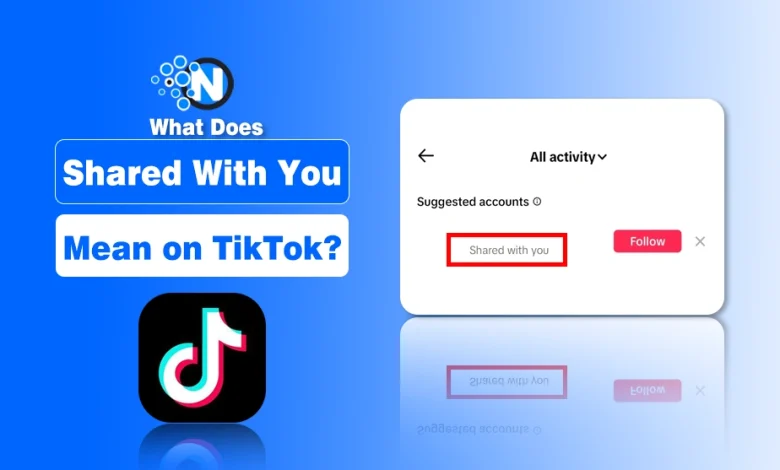

What Does Shared With You Mean on TikTok? Guide (2025)

If you have been scrolling through TikTok and noticed the label “Shared With You” on certain videos, you are not…

Featured Contents

22 hours ago

10 Best Web Hosting for Small Businesses in 2025

3 weeks ago

The 10 Best Budgeting Apps Of 2025

March 11, 2025

Understanding Advanced Technical SEO (2025 Guide)

March 10, 2025

What is On-Page SEO? Importance of Key Elements

March 10, 2025

10 Best Website Builders for Beginners to Use in 2025

March 1, 2025

10 Best SEO Blogs to Follow This Year

February 28, 2025

How to Start a Blog in 2025?

February 26, 2025

Top 10 Google Apps For Businesses in 2025

January 23, 2025